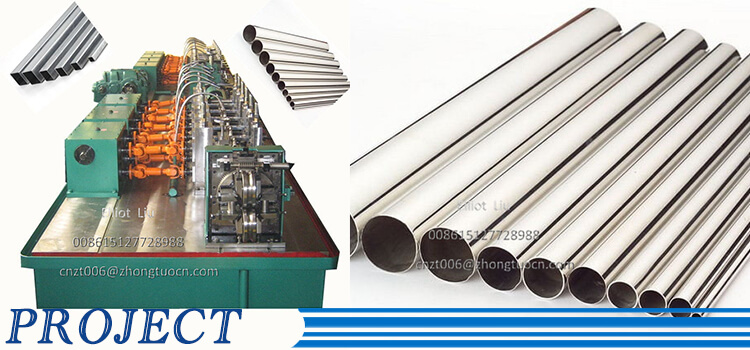

HG50 welded pipe machine, cantilever type pipe making roll forming machine

Here I will introduce HG50 welded pipe machine cantilever type. This machine is good for those who needs make various types small pipes within the wall thickness 0.5-3.0mm, and pipe diameter from 10-60mm. HG50 welded pipe machine also work at the speed of 30-80m/min.

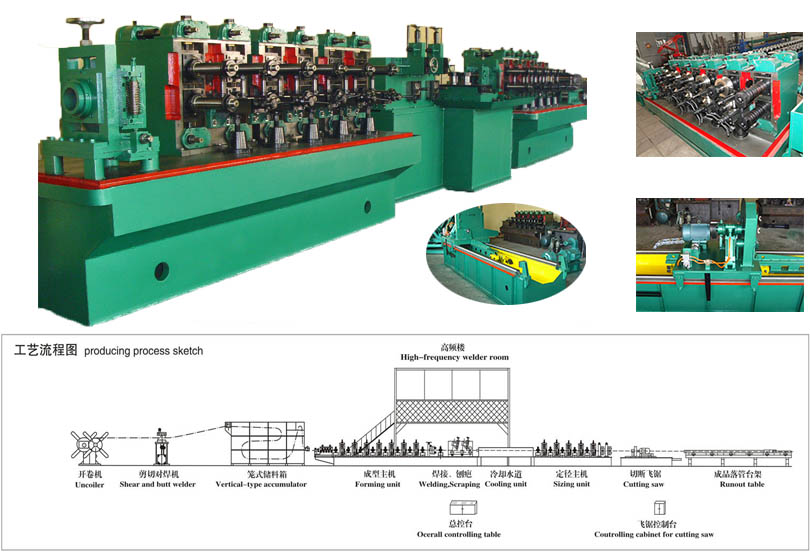

Working Principle:

For welding, it makes full use of two sciences-high-frequency current Skin-Effect and Adjacency Effect to make the current concentrate on the edge, then the temperature will reach to the point of welding. Then we can make the sheet to pipe by rolling and make the edge melting to one.

Features of HG50 welded pipe machine:

- Two types available for you to choose cantilever type and gantry type.

- Support various type materials like carbon steel, hot rolled coil, low carbon steel and others.

- Support material thickness from 0.5-3mm.

- Support pipe diameter from range 10-60mm.

- Easy and fast to change mould.

- Able to make various types pipes like round, square, oval and others.

- Lower energy consuming, lower workforce consuming and others.

Here are some basic parameters for your reference:

| Main elements introduction | ||

| Decoiler | Double head decoiler-inner expanding manual Material width: 39.88 200mm Material thickness: 0.4 2.0mm Outside diameter:900 1800mm Inner diameter: 500 520mm Max weight: 2500kg |

|

| Main roll formingmachine part: | Coil leveling and feeder part | 1 set |

| Rollers-horizontal(6) Diameter: Φ60mm Material: 40Cr |

cantilever type, change roller at the side of machine | |

| vertical roller: 5 sets Mode: Passive rotation |

Material: 45# steel Diameter: 30mm |

|

| Machine for removing weeded sacra | 1 set | |

| Guide roll stand for controlling direction of pipe seam to insure pipe seam flatly and straightly entering into extruding rollers. | 1 Set | |

| One set of extruding roll stand for controlling weld seam to realize successful welding. | 1 set | |

| Scraper frame for scraping outside weld seam | 1 set | |

| Installation bed along with forming machine | 1 set | |

| Water cooling device | 2 set | |

| Size diameter part | Mainly fine shaping pipe after welding and controlling size accuracy. | Horizontal roll stand and vertical roll stand.(structure same as forming device) |

| Roughly straightening machine frame | Type: Turk’s head type, 4 rolls two side | |

| One installation bed along with sizing main machine. | 1 set | |

| Drop tube stand: | It is welded frame type by plate, with part that can give signals for guiding the length. | |

| Runout table | Customize according to customer need. | |