High quality single layer roofing sheet roll forming machine

High quality single layer roofing sheet roll forming machine

High quality single layer roofing sheet roll forming machine has the same function to make roofing sheet. But different with the normal quality machine, it can use more than 10 years and has highly working speed. When machine working, it is fully automatic. It has independent stand as frame, machine frame thickness is thicker than 25mm. All the elements of the machine are world famous. Machine mould and shaft all use the best material, even if after long time using, it also can keep perfect shape.

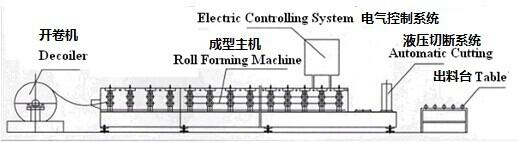

Working Process of single layer roofing sheet roll forming machine:

Uncoiling→ Feeding material into machine→ Roll forming→ Measuring length→ Step formed→ Auto cutting→ Products receiving

Main parameters of single layer roofing sheet machine:

| 1 | Length of the main part | About9500 1650 1500mm |

| 2 | Weight of main part | About 6.8 Ton |

| 3 | Voltage | 380V/50HZ3Phase (as customer’s request) |

| 4 | Roller fixer | Middle plate welded |

| 5 | Frame | Guide pillar and the thickness is 50mm |

| 6 | Frame thickness | 25mm |

| 7 | Drive mode | Gear |

| 8 | Material of rollers | 45# steel, surface hard chromium plating. |

| 9 | Material of shafts | 45# steel |

| 10 | Diameter of shafts | 90mm Solid shafts |

| 11 | Number of rollers | 16 rollers |

| 14 | Main power | 11kw(Simon motor ) |

| 15 | Text screen displayer | Japan made |

| 17 | Forming speed | speed 8-22m/min |

| 18 | PLC Control system | Japan Panasonic PLC |

| 19 | Hydraulic power | 5.5KW |

| 20 | Gear box | China famous brand |

| 21 | Chain | 1.25 |

| 22 | Delivery time | 30 working days after receiving the deposit |

What elements make machine high quality?

1.Machine frame thickness. High quality machine normally has high working speed. So when machine working, the steady ability is very important for you. 2.Machine shaft diameter and roller material. High quality machine can process thicker coil and work long time. So shaft hardness and diameter is very important against bending. 3.The roller material is very important. As for long time using, material will rub roller. Only good quality material can keep perfect shape after long time using. 4.Electrical elements brand. The machine controlled by PLC and powered by motor, so the brand and quality can affect the machine quality too much. Single layer roofing sheet machine video: https://youtu.be/WFYoDREY75M