High-Speed V-Steel Roll Forming Machine with Punching for Wall Angle and Corner Bead Production

Description of Corner Bead Roll Forming Machine

This machine is designed to produce wall angles, which are essential components for the installation of suspended ceiling grid systems within enclosed spaces. The grid system typically consists of multiple main runners and hanger wires that suspend these runners from the room’s overhead structure. The wall angle features a long body that, when viewed in cross-section, forms an angular profile with one side connecting to another extending side.

Along the length of the wall angle, there are three distinct sets of markings:

– The first set of marks appears at consistent one-foot intervals along the body. These markers indicate where the main runners and hanger wires should be attached.

– A second set of marks is positioned at different intervals, usually every sixteen or twenty-four inches, to denote the points where the wall angle should be fastened to the vertical wall studs of the enclosure.

– The third set of markings is used to define the overall dimensions of the grid structure, including its height and length. Each mark in this series actually comprises a pair of indicators placed on both sides of the wall angle’s body. These pairs form opposing, triangular-shaped notches that can be scored to create channels for holding resilient marking elements.

These features ensure that the wall angles produced by the machine are ready for accurate and efficient assembly, contributing to the stability and aesthetics of the suspended ceiling grid system.

Profile Drawing and Application:

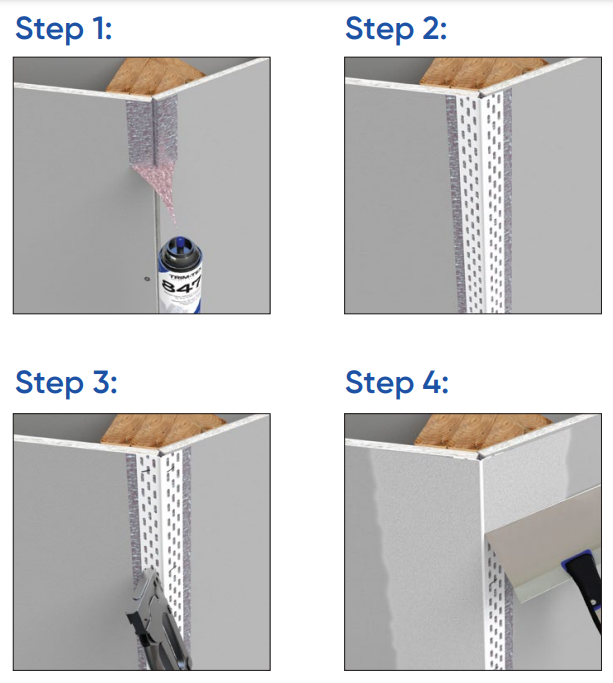

Before Installation:

Begin by measuring, cutting, and dry-fitting the bead, ensuring to leave a ½” gap from the floor.

Step 1:

Apply spray adhesive to both the bead and the edge of the drywall.

Step 2:

Position the bead and press it firmly in place, applying pressure to the mud legs.

Step 3:

Secure the bead by stapling every 6”-8” using ½” staples.

Step 4:

Complete the installation by applying drywall compound.

The Technical Specifications Of The Corner bead Roll Forming Machine:

| Corner bead rolling forming machine | ||

| 1.Formed Material | PPGI | Thickness: 0.4-0.6 mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 12rows(As your requirement) |

| Diameter of shaft | 45mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 3T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 0-70m/min(without knurling) 0-60m/min(with knurling) | Speed is adjustable according to customer’s request |

More pictures of the machine: