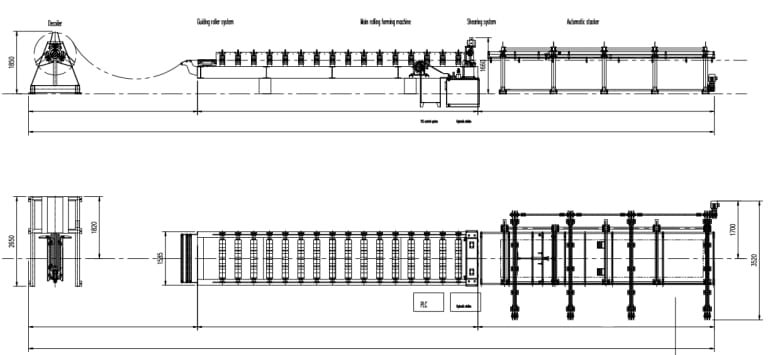

Processing Flow

Decoiler-feeding material-roll forming-cutting-receiving the product

Technical Specifications: The ZTRFM Metal Deck Roll Forming Machine is built for robustness and precision. The frame is constructed from 400 H beam steel, with middle plates of 20mm thickness. It features Gcr15 quenched steel rollers that can handle galvanized coils with a yield strength of up to 550 Mpa and thickness from 0.8-1.5mm. The machine is equipped with a dual 18.5kw motor, ensuring high-speed forming at up to 15 meters per minute.

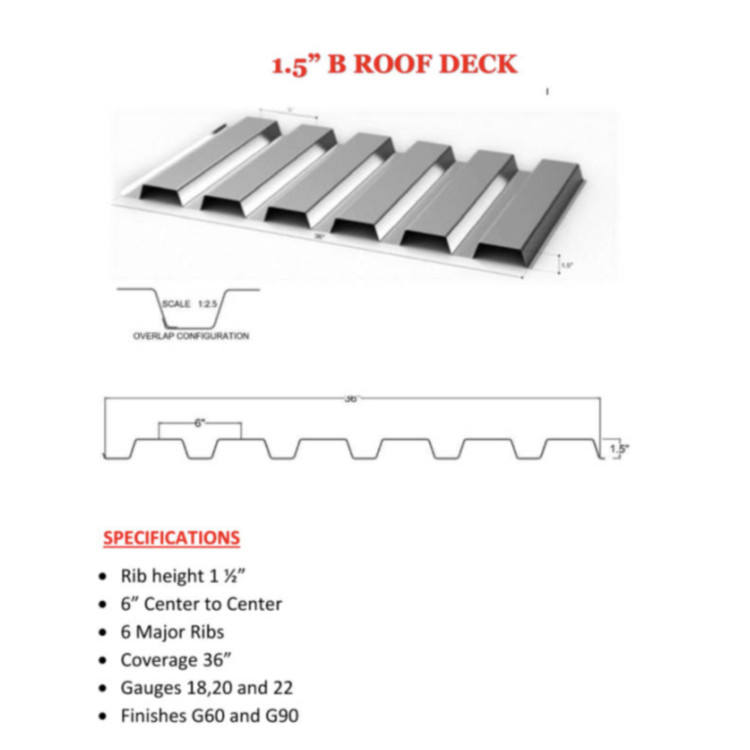

PRODUCT DISPLAY

|

12 tons hydraulic decoiler with loading car

Loading capacity: 12t Coil width: up tp 1250mm Coil ID: 480-610mm Hydraulic expansion Electric motor mandrel drive Hydraulic motor : 5.5kw Drive motor : 7.5kw |

|

|

User-Friendly Feeding Device: The feeding device is equipped with rubber

rollers to protect the material surface and adjustable handwheels for

accommodating different thicknesses.

|

|

|

Roll forming device

1.rollers Gcr15 quenching treat HRC58-60 good hardness for long service time. 2.Each roller has number and with keynotes, it can fix on the shaft stablely |

|

|

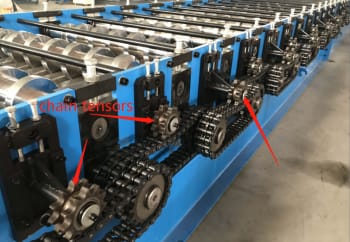

Reliable Transmission System: The machine features a double-chain

transmission system with chain tensors, ensuring consistent and reliable operations.

|

|

|

Unmatched Shearing Power: Equipped with a robust 7.5kw motor and a dual oil

cylinder system, our machine provides stable and powerful shearing. It can

effortlessly cut through materials up to 1.5mm thick, significantly

outperforming those with single oil cylinders.

|

|

|

Intuitive PLC Control System: Featuring a Delta PLC and inverter, along with

Schneider electrical parts and an Omron encoder, our control system offers full

automation and ease of operation. The system can be configured for operation

in English, with customization available for other languages.

|

|

|

Robust Hydraulic Station: Our hydraulic station features a cooling system and

a 7.5kw motor, guaranteeing consistent performance even under long working hours.

|

|

|

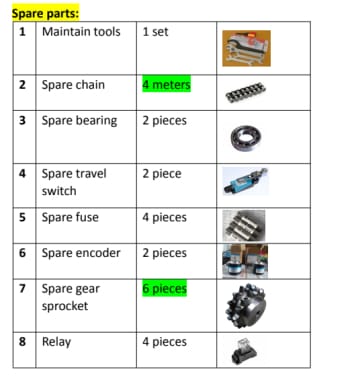

Inclusive Spare Parts: With a 2-year warranty, our machine comes with a range

of spare parts from renowned brands like Siemens and Schneider, ensuring uninterrupted operations

|