Metal steel floor Webdeck roll forming machine

Metal steel floor Webdeck roll forming machine

It adopts latest designs. Its shearings structure is the most advanced among China supplier.

The design of inner structure of pillar is our patent.

Besides, all parts of this Steel structure floor deck forming machine are top quality to ensure perfect working.

Main parameters of the Steel structure floor deck forming machine

| Item | Name | Description |

| 1 | Decoiler | Capacity:5 tons |

| 2 | Forming station | 28 stations |

| 3 | Motor power | 30kw |

| 4 | Transmission | By double chain |

| 5 | Speed | 12-15m/min |

| 6 | Roller material | Bearing steel with quenched treatment,chromed on the surface |

| 7 | Shaft material | 45# steel with tempering treatment,95mm diameter |

| 8 | Cutting type | Hydraulic cutting |

| 9 | Cutting material | Cr 12 with quenched treatment |

| 10 | Hydraulic power | 7.5 kw |

| 11 | Control system | PLC |

| 12 | Electric brand | Delta,Siemens,Schneider |

| 13 | Voltage | 380V,500HZ,3PH(or as customers’ request) |

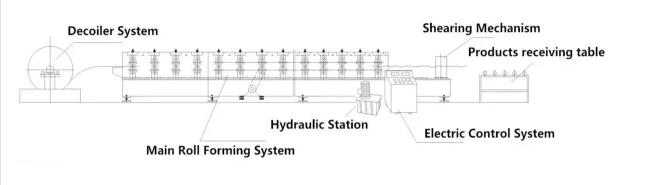

Working process of Steel structure floor deck forming machine

Decoiling–embossing–roll forming–hydraulic cutting–run-out table

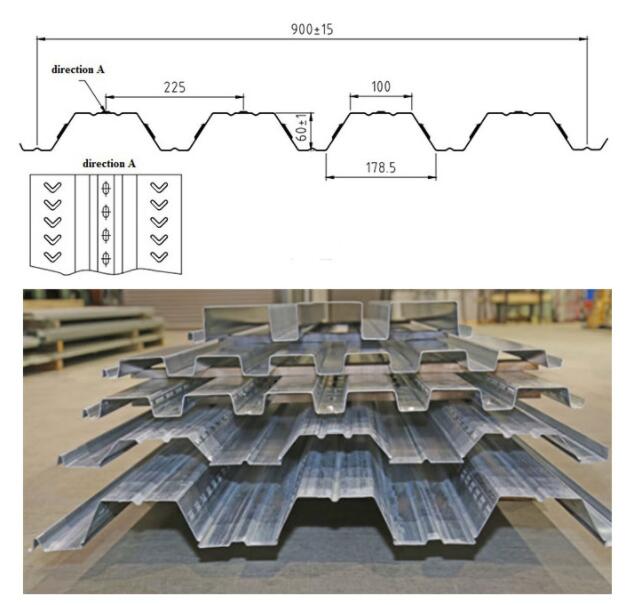

Profile Drawings of Steel structure floor deck forming machine

we can offer professional CAD drawings of Steel structure floor deck forming machine according to your requirement,we also can design the machine as customer’s profile

Metal steel floor Webdeck roll forming machine

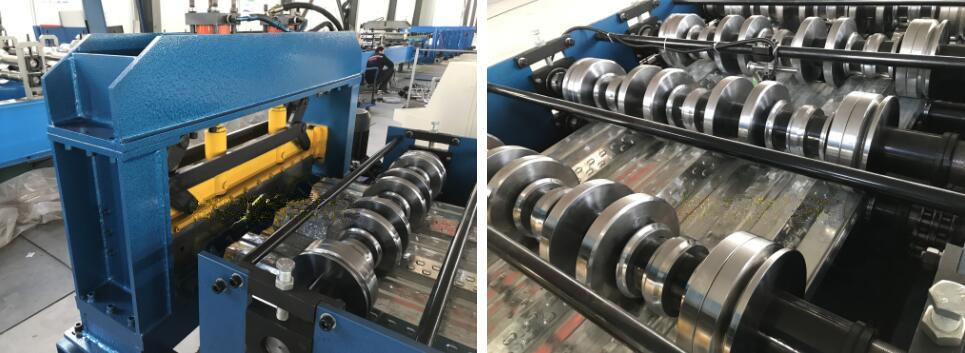

Compared with normal rollers, this new model roller quench twice times and prolong heat treatment time.

Feeding part of Metal steel floor Webdeck roll forming machine

the support shelf support raw material to go inside of machine smoothly.

Main roll forming machine

Good cutting design.

Adopt double chain which can guarantee the stable of the machine working.

Add the loading hook which is easy for load the machine.

Add the flat screw which can adjust the ground surface.

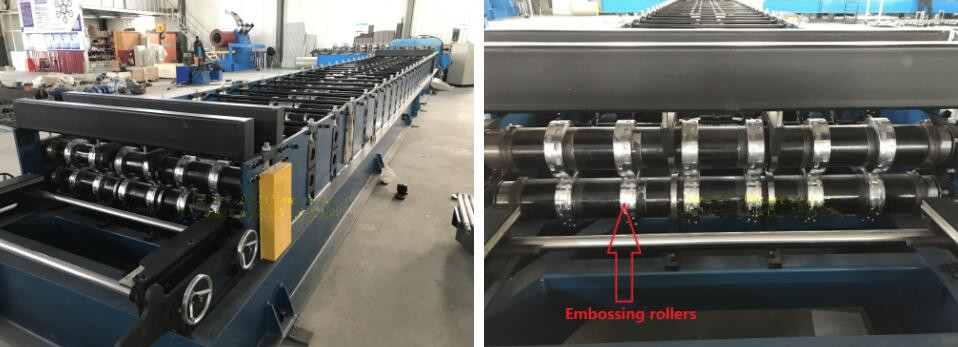

Hydraulic station of Metal steel floor Webdeck roll forming machine

To improve stability and prolong life time, this machine adopts powerful 7.5 KW hydraulic station.

it adopts national standrad motor.