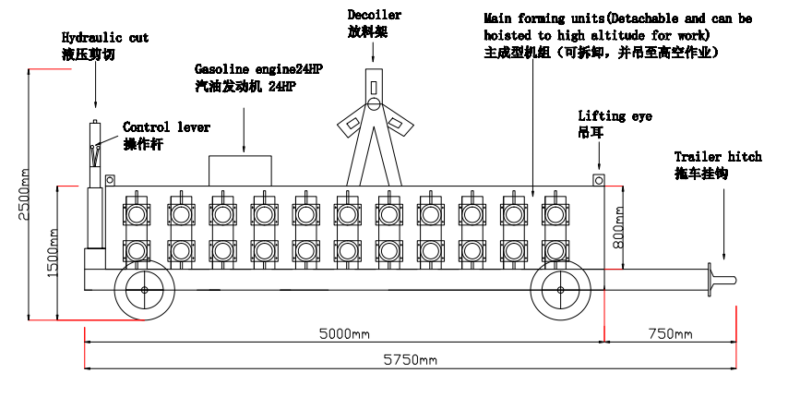

Mexico Popular KR-18 KR-24 Portable Standing Seam Roof Roll Forming Machine

Work Flow:

Dimensions: 24″ and 18″ wide by 3″ deep

Slope: 1/4:12

Panel Attachment: Concealed Fastening System; Low, High, Fix, Sliding

Gauges: 24 (standard); 22, 26 (optional)

Finishes: Smooth (standard); Embossed (optional)

Lengths: 55′ maximum is standard but longer lengths available by special request

Fasteners: The clips are available as sliding or fixed. two different clip heights are available to allow for thermal blocks.

Features and Benefits of the Standing Seam Roof Roll Forming Machine

| Material Thickness | 0.25-0.8mm PPGI and GI |

|

| NO. of Roller Stations | 18 stations | |

| Material for Rollers | 45# steel polished and coated

with chrome HRC58-62° |

|

| Material for Shaft | High grade 45# steel polished(CNC lathe) | |

| Diameter of Shaft | 70mm(Solid shaft) | |

| Frame Panel | 16*290*580mm | |

| Bottom Frame | 350x6mm H steel | |

| Motor Power | 5.5 KW(shanghai motor) | |

| Driven Type | Wall Plate Chain Drive | |

| Chain and Gear | 1″, 17 teeth sprocket, 50 link chain | |

| Speed | About 15m/min |

Key Features

- Elimination of Panel Penetration: The system is designed to minimize panel penetration throughout the building envelope, except at the end laps and panel ends, which are secured using a robust compression joint.

- Pre-Installed Sealant: Side laps arrive at the construction site pre-equipped with sealant, simplifying installation and enhancing weather resistance.

- Factory Notching and Pre-Punched Holes: Each panel is factory-notched at both ends and includes pre-punched holes to ensure accurate alignment and quick assembly.

- Reinforced End Laps: The 16-gauge backup plates, complete with pre-punched holes, provide added strength and maintain proper fastener spacing.

- Versatile Clip Options: Available in both high and low clip configurations to accommodate various needs.

- Certified Ratings: Panels meet UL® 90 and FM standards, ensuring exceptional performance and reliability.

- Snap-Together Interlocking: Panels are engineered to interlock seamlessly by snapping together, enabling quick and secure installation.

Notable Benefits

- Precise Alignment and Solid Connections: Pre-punched holes ensure fastener spacing is consistent, improving installation accuracy and providing solid connections at end laps.

- Enhanced Weather Resistance: The pre-installed sealant in the side laps contributes to a weather-tight system, effectively sealing out the elements.

- Flexible Installation: Panels can be installed starting from either end of the structure, offering flexibility on the job site.

- Adaptable Insulation Compatibility: The design accommodates a wide range of insulation systems, including 1-inch thermal spacers at the purlins.

- Lower Insurance Premiums: The system’s certified performance ratings can lead to reduced insurance costs.

- Ease of Use: With no need for additional seaming equipment, installation is faster and more cost-effective.

This advanced panel system provides a comprehensive solution for durable, weather-resistant construction with simplified installation, making it an excellent choice for a variety of building applications.