Zhongtuo high quality elevator guardrail machine, hollow guardrail with punching holes professionally for elevator

Zhongtuo engineers guardrail roll forming machines for a wide range of elevator designing products including steel guardrails and signposts, and more than 16 years experience makes us have high standard quality requirement and high through-put. The principle of this machine is cold roll forming, so this machine cannot be used to make thickness beyond 5mmm material.

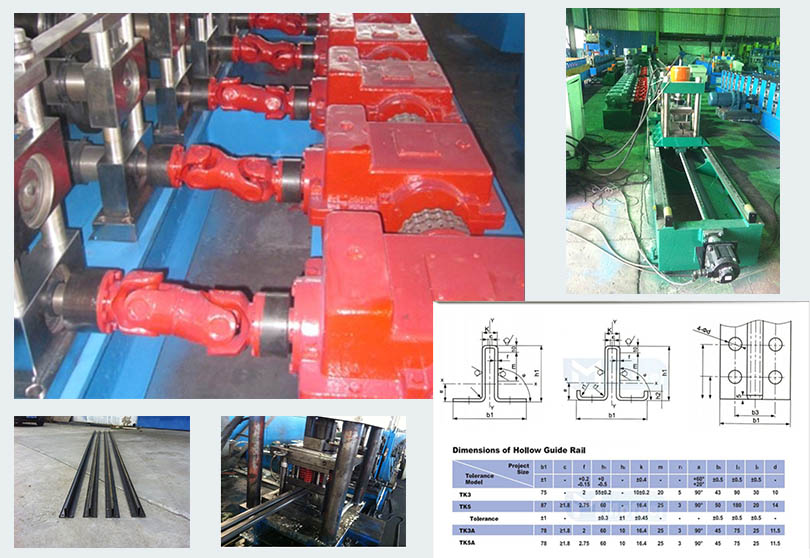

Here are machine basic information about Zhongtuo elevator guardrail roll forming machine.

Machine element and its price:

| 3T decoiler | 1 |

| Forming machine-punching and shearing | 1 |

| PLC station | 1 |

| Hydraulic station | 2 |

| Case of differential and gear box | 1 |

| Rouout table | 1 |

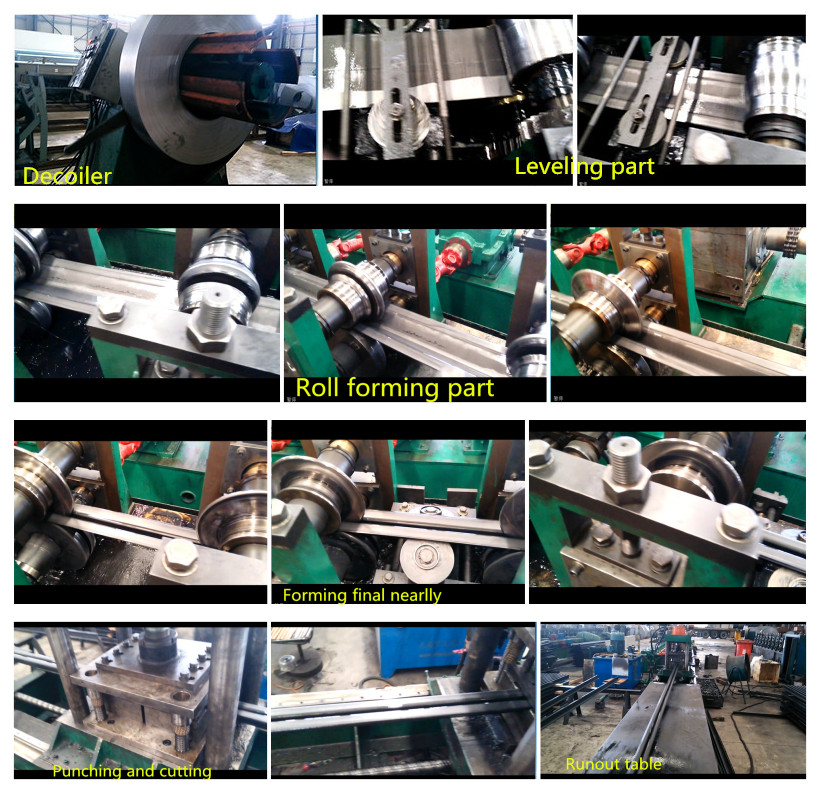

Check the whole working process from the following pictures:

Main features of each part

Shearing part/hearing method/It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

(2)Material:GCR12/Quenching Oil HRC58-62

(3)Length :Automatically cut in specified length

(4)Error in length ±1.5mm

Counter:Panasonic

(1) Voltage:380V 50HZ phase adjustable

(2) Control length automatically

(3) Production counting automatically

(4) Computer controls length and quantity for finishing production in specified amount.

(5) Fix error automatically and accurately.

(6) control method: Touch and button

Zhongtuo high quality elevator guardrail machine has been widely used in famous factories both home and abroad. This machine could work totally full automatically and one person could run this machine. For tech support, we provide 7/24 service, free installation, training till everything is ready for customers.

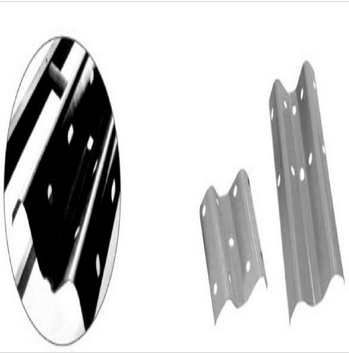

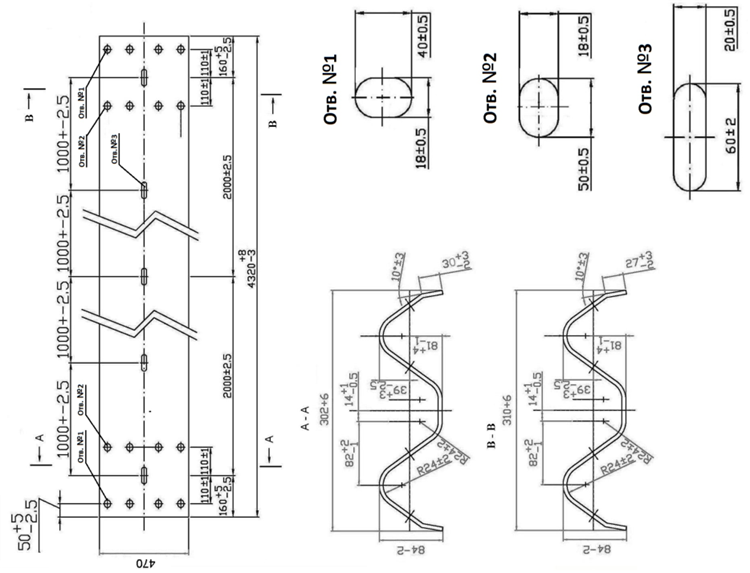

When you need to get the detail quotation, please provide your drawing profile. Here is one finished product for your reference: