Light steel frame villa roll forming machine

Light steel frame villa roll forming machine

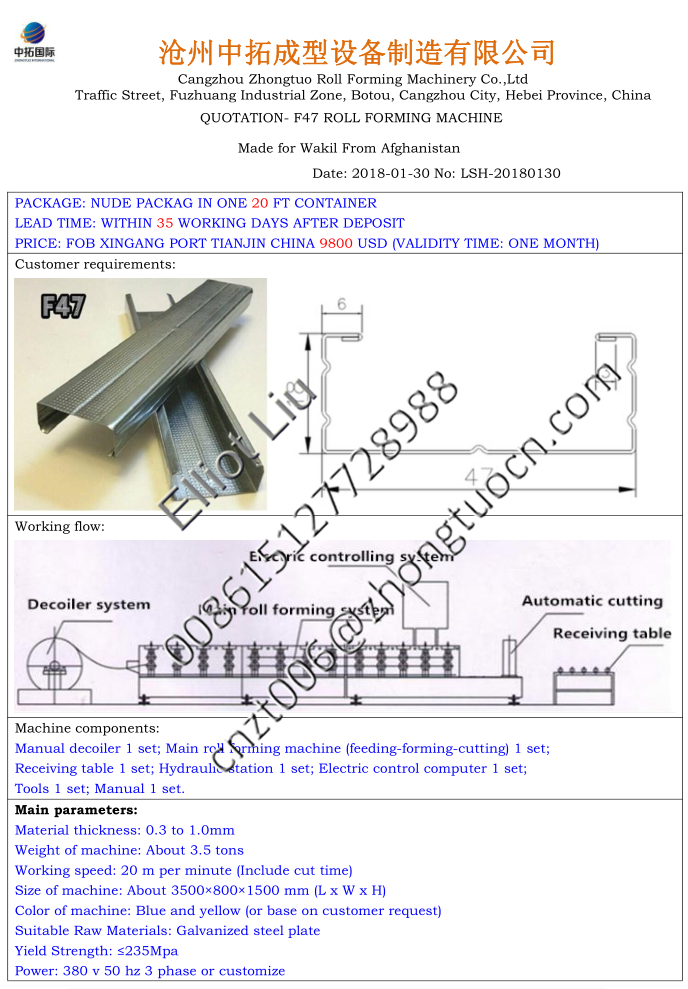

Summary We are a new high-tech enterprise who owns many proprietary technology in China. We keep focusing on researching and developing different roll forming machines. We lead to a new age of steel producing area and have quantities of customers oversea. Help you create a light steel system which is not only suitable for Chinese market but also suitable for international market. According to different requirements of users, we can design and manufacture different kinds of light steel frame forming machines, which is utilized to produce various steel structure formed steel, such as light steel keel. The machine is mainly composed of decoiler, roll former, cutting device, product table, and control cabinet, etc.  The frame of the light steel forming machine adopts formed steel construction and after welded, this machine utilizes integrity processing technology. It enjoys rational and beautiful structure, strong carrying ability, and stable and reliable performance. The forming roller of this machine is designed by professional technicists. The machine undergoes high precision processing and heat treatment before chromeplate. So this machine is characterized by high forming precision and long service life. The main components of this device are from products of famous brands, thus ensuring the whole performance and quality. Controlled by PLC, this machine is easy to operate, thus workers without special training can operate it very well. This equipment is convenient to debug, and enjoys low noise and high efficiency. Different Software Optional: You can choose different software, which reduces your investment risk.

The frame of the light steel forming machine adopts formed steel construction and after welded, this machine utilizes integrity processing technology. It enjoys rational and beautiful structure, strong carrying ability, and stable and reliable performance. The forming roller of this machine is designed by professional technicists. The machine undergoes high precision processing and heat treatment before chromeplate. So this machine is characterized by high forming precision and long service life. The main components of this device are from products of famous brands, thus ensuring the whole performance and quality. Controlled by PLC, this machine is easy to operate, thus workers without special training can operate it very well. This equipment is convenient to debug, and enjoys low noise and high efficiency. Different Software Optional: You can choose different software, which reduces your investment risk.

Light Steel Frame Villa Performance: 1)Lifetime for structure: 50 years. 2)Earthquake resistance: Max. more than 8 grades. 3)Wind resistance: max 64m/s. 4)Fire resistance: all the materials used can be fire resistance. 5)Snow resistance: max 2.9KN/m as required 6)Heat insulation: 100 mm in thickness can match 1 m thickness of brick wall. 7)High acoustic insulation: 60db of exterior wall 40db of interior wall 8)Insect prevention: Free from the damages by insects, such as white ants 9)Ventilation: a combination of natural ventilation or air supply keep the indoor air fresh and clean 10)Packing and delivery: 140SQM/ 40’HQ container for structure only and 90SQM/ 40’HQ container for structure with decorate materials. 11)Installation: the average is one worker one day install one SQM. 12)Installation guide: dispatch engineer to guide on site.

Light Steel Frame Villa Performance: 1)Lifetime for structure: 50 years. 2)Earthquake resistance: Max. more than 8 grades. 3)Wind resistance: max 64m/s. 4)Fire resistance: all the materials used can be fire resistance. 5)Snow resistance: max 2.9KN/m as required 6)Heat insulation: 100 mm in thickness can match 1 m thickness of brick wall. 7)High acoustic insulation: 60db of exterior wall 40db of interior wall 8)Insect prevention: Free from the damages by insects, such as white ants 9)Ventilation: a combination of natural ventilation or air supply keep the indoor air fresh and clean 10)Packing and delivery: 140SQM/ 40’HQ container for structure only and 90SQM/ 40’HQ container for structure with decorate materials. 11)Installation: the average is one worker one day install one SQM. 12)Installation guide: dispatch engineer to guide on site.  Light Steel Frame Villa Appearance: Building overall looks attractive Internal is covered by color steel plate Structure and color are matched coordinately

Light Steel Frame Villa Appearance: Building overall looks attractive Internal is covered by color steel plate Structure and color are matched coordinately