Roof Tile Roll Forming Machine

Roof Tile Roll Forming Machine

We are professional roof tile roll forming machine manufacturer, our city located in Botou county, Cangzhou city, Hebei province.

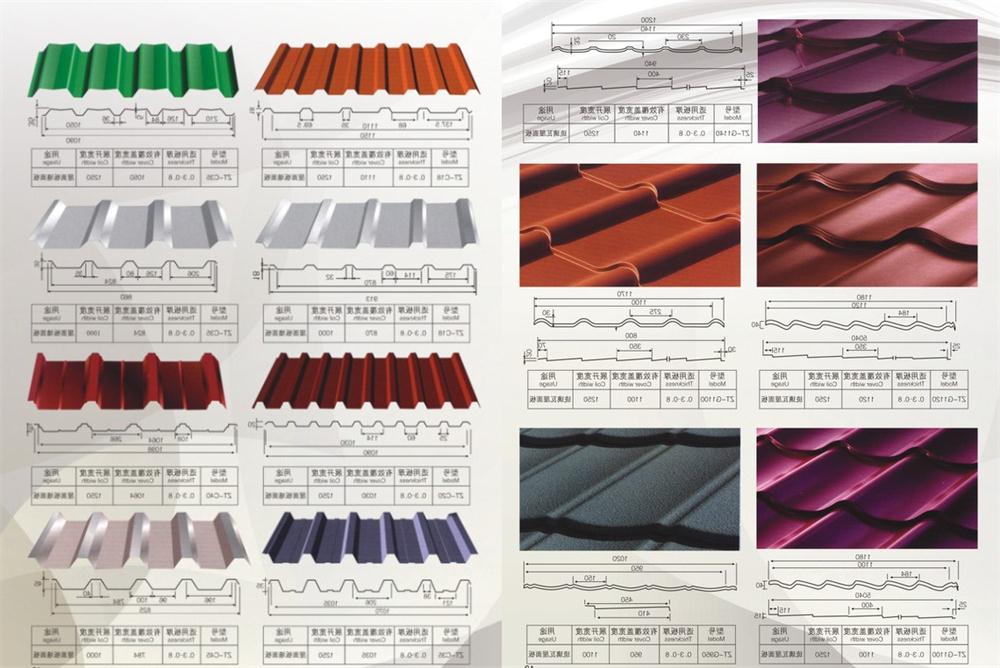

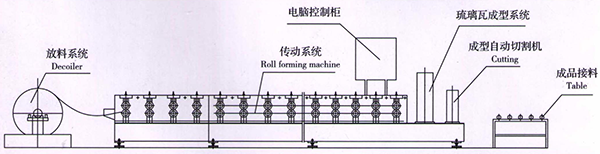

We can produce many different kinds of roof tile roll forming machine for the

customer. Our machine can use the steel coils thickness from 0.3 mm to 1.0 mm.

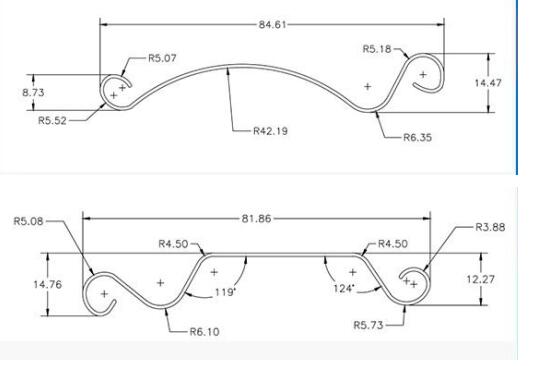

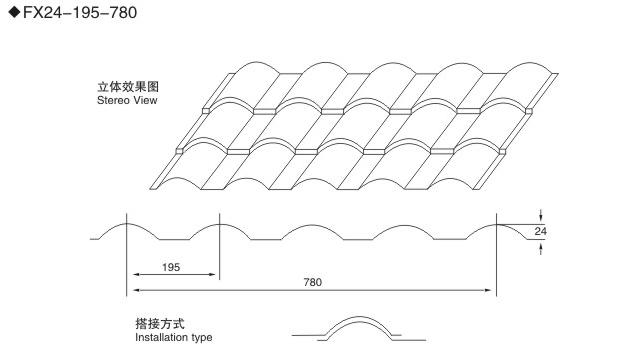

Our machine are customized, if the customer have their drawing, then we can design

the roof tile machine as customer’s drawing. If the customer are not familiar with the roof tile drawing,then we can send our tile drawings catalogue to the customer to let them have a choose.

Our machine have exported to more than 70 countries until now, our machine is good quality with low price. we can produce both the automatic machine and the half automatic machine for customer.

We sincerely invite you come to our factory to have a visit if you have time, we are sure we will let you satisfied.