CZ Shape Changeable Purlin Production Line

CZ Shape Changeable Purlin Production Line

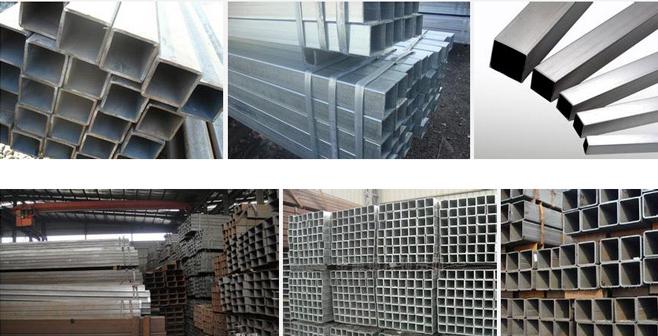

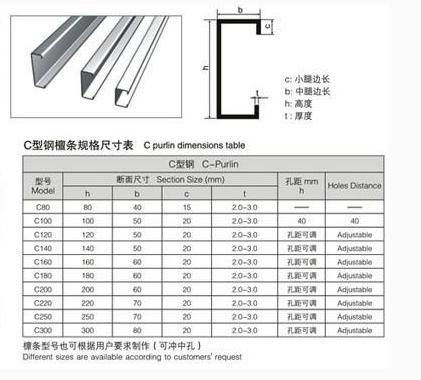

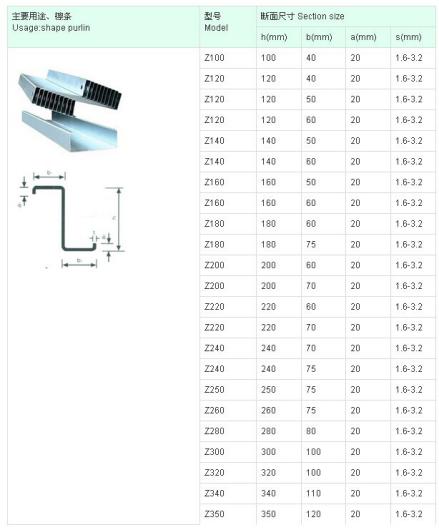

C or Z shape purlins are made from hot/cold rolled steel strips,and straightened,hole punched,cut to length,and roll formed by C/Z changeable shape purlin roll forming machine. Through changing, this product line can make the change of the shape C or Z purlin,besides change different size of C or Z shape purlin,This change for shape and sizes of C/Z purlin can be realized by automatic mode.

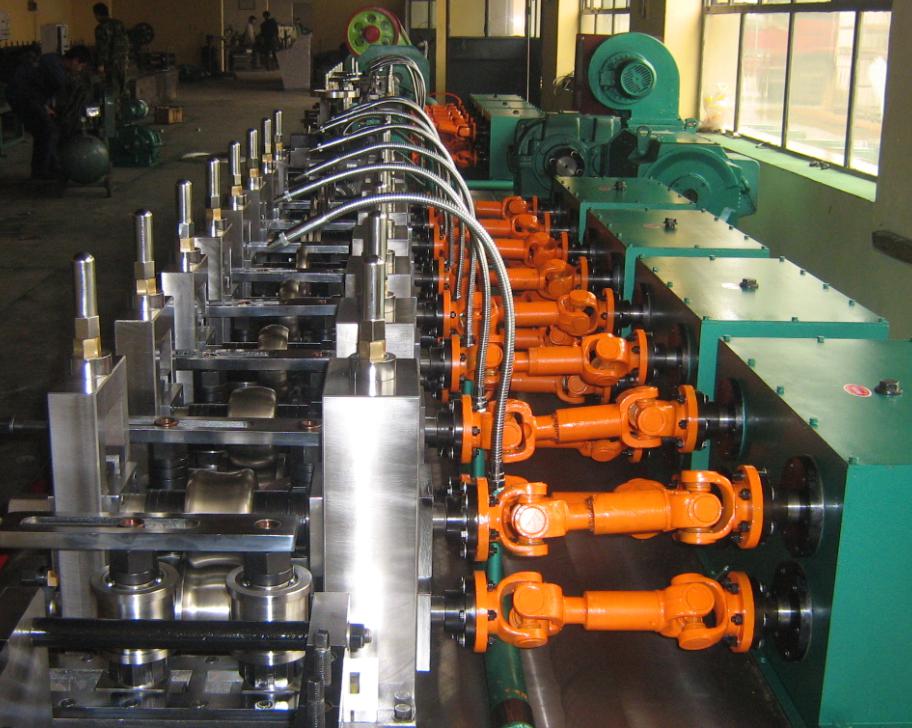

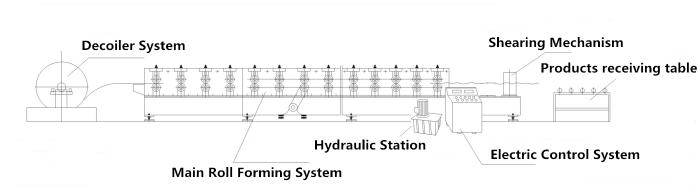

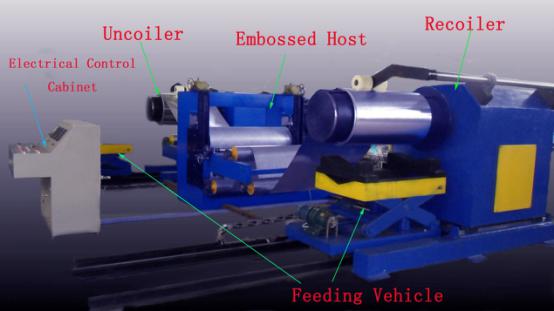

C/Z shape purlin product line consists of uncoiling system,straightening system,hole punching system,shearing system,roll forming system,products support table,hydraulic system,automatic controlling system,and so on. It’s a high efficiency equipment of making purlin,which is suitable for current enterprises.

Working Flow

Uncoiling-Sheet Guiding-Straightening&Levelling-Hole Punching-Measuring Length&shearing-Roll Forming-Sheet to support table

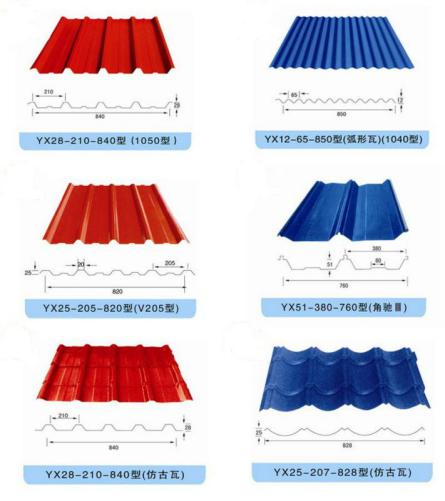

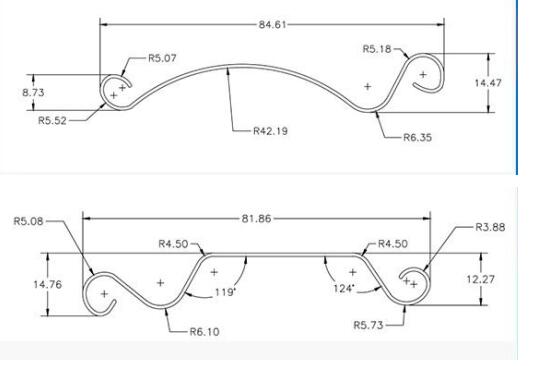

Standard drawing

Main Technical Parameters

| Item | Parameters | ||

| Profile | C and Z purin | ||

|

Material |

Type | Steel strip | |

| Thickness (mm) | 1.0-3.2 | 1.0-3.0 | |

| Yield Stress(Mpa) | 230-300 | 300-350 | |

| Max.Forming speed(m/min) | 16-18 | ||

| Roller Material | D2 | ||

| Roller driven type | Hydraulic motor driven | ||

| Controller | PLC | ||

| Operation | Touch screen and button | ||

| Hydraulic system pressure(MPA) | 25 | ||

| Hydraulic station motor power(KW) | 7.5 | ||

| Total power(kw) | 30 | ||

| Total weight(kg) | about 12000 | ||