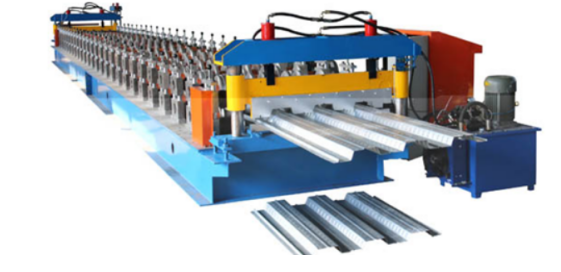

High speed roofing sheet roll forming machine

High speed roofing sheet roll forming machine

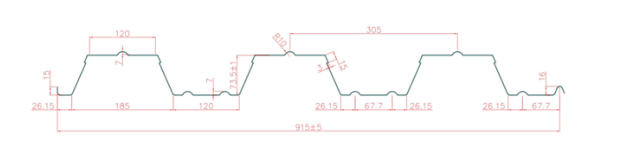

High speed roofing sheet roll forming machine is designed based on the normal speed roofing sheet machine, it can reach working speed of 45m/min. The drawing profile could be any type. Different with the tradtional roofing sheet machine, it uses high strong frame with machine cooling down system, using gearbox as the transmission method. In the following part, I will take a random popular drawing profile for example, to show how the machine is designed.

High speed roofing sheet roll forming machine pictures for your reference:

Here are some parameters of high speed roofing sheet roll forming machine for your reference:

5 ton hydraulic uncoiler with loading car,feeding cutter,roll forming machine,forming cutter,Siemens control box,cutting device,hydraulic system,Siemens PLC control system, 12M auto stacker with 3m side run-out conveyor and auto leveling.

| Main Forming

machine |

Forming steps stations | 20 roller stations |

| sheet | Sheet feeding guider | 1 set |

| Roll forming speed | 40 M/Min | |

| Total Power: | Total Power | 85HP |

| Shaft diameter | 85mm material S45C with hardern and grinding | |

| Design type | Memorial arch | |

| roller material | GCr12MoV steel | |

| shaft material | 40Cr steel | |

| Transport | By gear | |

| Power of main machine | 11kw | |

| Type of cutting | Hydraulic | |

| Cutting tolerance | ±1mm | |

| Cutter | SKD-11 with feeding hardern HRC 58-60 | |

| Length setting | By encoder 2 set | |

| Working pressure | 40MPA |

Features of High speed roofing sheet roll forming machine:

Features of High speed roofing sheet roll forming machine:

- Working speed could reach 45m/min.

- Any type drawing profile could be high speed type.

- Flying cutting system.

- Gearbox transmission to make machine working steady and long time to use.

- Strong machine frame

- Water cooling system.

- Hydrailic cooling down system.

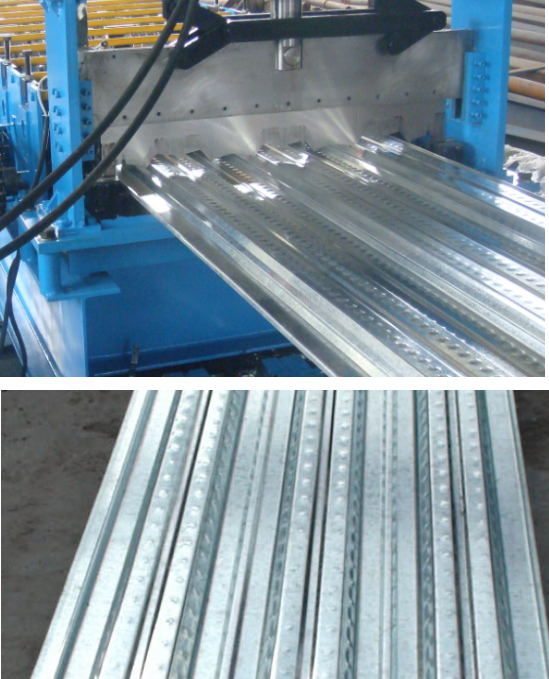

There are more pictures of high speed roofing sheet machine for your refernece:

ngs and then we design the machine for you.

ngs and then we design the machine for you.