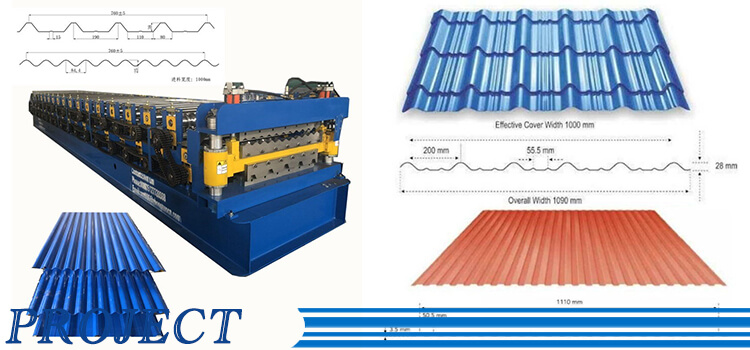

ZT-840/980 Double layers color steel roll forming machine

ZT840/980 Double layers color steel roll forming machine

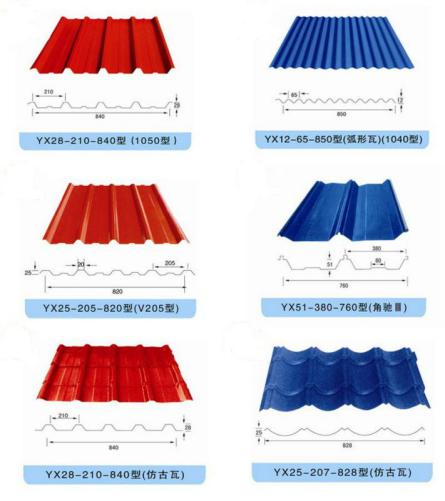

ZT-840/980 Double layers color stee roll forming machine using the latest double layer design,one machine using two type plates ,small footprint,easy to transport,saving costs.Our sales service,can do special design and manufacture according to user requirements,Meanwhile the user guide, production, installation, commissioning maintenance.

Details:

The features of the 840/980 Double layers color steel roll forming machine:

850/860 Double layers color steel roll forming machine adopt a high level of automatic control software, production information management.

The entire unit automation control system uses highly integrated network,make the automated system better performance.

850/860Double layers color steel roll forming machine also has the operation, maintenance, maintenance and mechanical commissioning mold advantages of easy replacement.

850/980Double layers color steel roll forming machine Affordable,can synthesize one machine of the two models,that saves floor space, but also costs far less than the two double single machine,it is the user’s preferred.It is widely used all-steel plant frame, single-sided color plate steel plant, multi-span steel structure workshop, with wooden beams driving workshop, villa-style office buildings and even across the color plate color steel ceiling, roof and floor, span Workshop, shed light steel ring.

Color fixation equipment installation have transmissive and a dark button concealed in two.Transmissive fixation is the most common way to color-coated steel roofing and siding installation of equipment,That is self-tapping screws or rivets color plates fixed to the support member (eg purlins) on,transmissive fixed into a fixed crest trough fixed or their combination.Dark button concealed fixation is with dark button color plate supporting the special dark button first fixed to the support member (eg purlins) on,Color plate fixation parent center rib and rib ratcheting buckle dark, usually used for roof mounting.

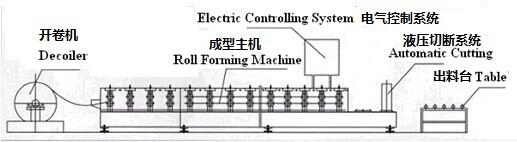

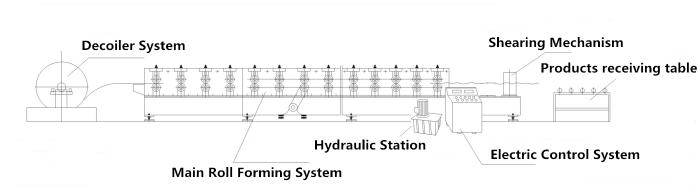

Combined C U Roll Forming Machine Entry Beach Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

Combined C U Roll Forming Machine Entry Beach Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.  Combined C U Roll Forming Machine Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission, roller surfaces polishing, hard plating , heat treatment and galvanize treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Size of main part: About 5.5*1.4*1.5m (L*W*H) Weight of main part: 4.5Tons Main power: 5.5kw Voltage: 380V/50HZ/3Phase Frame type: Memorial arch frame Frame thickness: 25mm Drive mode: By gear Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: φ40mm Number of rollers: 11 rollers Material: GI/PPGI Material thickness: 0.3-0.6 mm Forming speed: 25 meter/minute

Combined C U Roll Forming Machine Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission, roller surfaces polishing, hard plating , heat treatment and galvanize treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. Size of main part: About 5.5*1.4*1.5m (L*W*H) Weight of main part: 4.5Tons Main power: 5.5kw Voltage: 380V/50HZ/3Phase Frame type: Memorial arch frame Frame thickness: 25mm Drive mode: By gear Material of rollers: GCr12MoV Material of shafts: 45# steel with tempering Diameter of shafts: φ40mm Number of rollers: 11 rollers Material: GI/PPGI Material thickness: 0.3-0.6 mm Forming speed: 25 meter/minute

Combined C U Roll Forming Machine Automatic Cutting Feature : Ensure stability, precision and cutting speed Function : Automatic cutting controlled by electric control system It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Gcr12MoV quenched Power supply : Hydraulic power

Combined C U Roll Forming Machine Automatic Cutting Feature : Ensure stability, precision and cutting speed Function : Automatic cutting controlled by electric control system It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Gcr12MoV quenched Power supply : Hydraulic power  Combined C U Roll Forming Machine Hydraulic Station It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Station quantity: 2 sets Hydraulic motor Power: 3kw Hydraulic oil: 46# hydraulic oil Volume: 30L Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves.

Combined C U Roll Forming Machine Hydraulic Station It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Station quantity: 2 sets Hydraulic motor Power: 3kw Hydraulic oil: 46# hydraulic oil Volume: 30L Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves.  Combined C U Roll Forming Machine Electric Control System 1. Adopted PLC, transducer, touch panel to ensure high speed with stability, precision and lifetime. 2. Voltage: 380V/50HZ/3Phase 3. Language: English and Chinese 4. Automatic length measurement 5. Automatic quantity measurement 6. Length Tolerance: 3m±1.5mm 7. Length inaccuracy can be amended easily. 8. Operating panel: touching screen and button together. 9. Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Combined C U Roll Forming Machine Electric Control System 1. Adopted PLC, transducer, touch panel to ensure high speed with stability, precision and lifetime. 2. Voltage: 380V/50HZ/3Phase 3. Language: English and Chinese 4. Automatic length measurement 5. Automatic quantity measurement 6. Length Tolerance: 3m±1.5mm 7. Length inaccuracy can be amended easily. 8. Operating panel: touching screen and button together. 9. Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.  Combined C U Roll Forming Machine Warranty 1. One year warranty, whole life technical support. 2. Installation & adjustment : We can take a video for the customer and the customer can also come to our factory, we can train customer how to install and adjust the machine. 3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day salary. Contact information

Combined C U Roll Forming Machine Warranty 1. One year warranty, whole life technical support. 2. Installation & adjustment : We can take a video for the customer and the customer can also come to our factory, we can train customer how to install and adjust the machine. 3. Oversea service: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day salary. Contact information