Roofing Sheet Making Machine For Algeria

Detailed Product Description

Basic Info

| Model No.: ZT | Tile Type: Colored Steel |

| Certification: SGS, CE, ISO | Condition: New |

| Customized: Customized | Usage: Roof, Wall, Floor |

| Transmission Method: Hydraulic Pressure | Control System: PLC Control |

| After Sale Service: Engineer Available To Service Machine Abroad |

Certificate: CE/ISO9001 |

| Transmission: By Chain | Width Of Material: Accroding To Client’s Request |

| Cutting Device: Hydraulic Cutting | Payment: By T/T |

| Package: With Water Proof Paper | Warranty: 5 Years |

| Product Name: Glazed Roof Sheet Forming Machine | |

Additional Info

| Packaging: Main machine is packed with water proof paper, the computer control box is packed by carton box |

Productivity: 30 sets per month |

| Brand: KAIYITE | Transportation: Ocean,Land,Air |

| Place of Origin: China | Supply Ability: 30 sets per month |

| Certificate: ISO9001/CE | HS Code: 84552210000 |

| Port: Tianjin Port,Shanghai Port,Qingdao Port | |

Product Description

Roofing Sheet Making Machine For Algeria

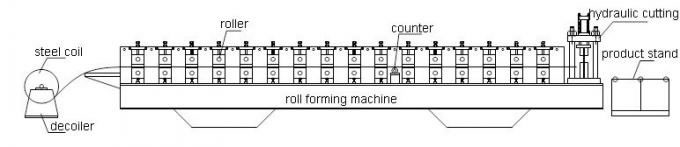

Some client want to know what the roofing sheet making machine is . Actually this equipment belong to the cold bending machinery . It can form the metal roof sheet ( the roof sheet profile is according to the client requirement) by pressing several steps . The Metal Roof Roll Forming Machine has the PLC control system , we can set the length and pieces by entering the data in the PLC , so that the machine will cut the roof sheet into the setted length and quantity .

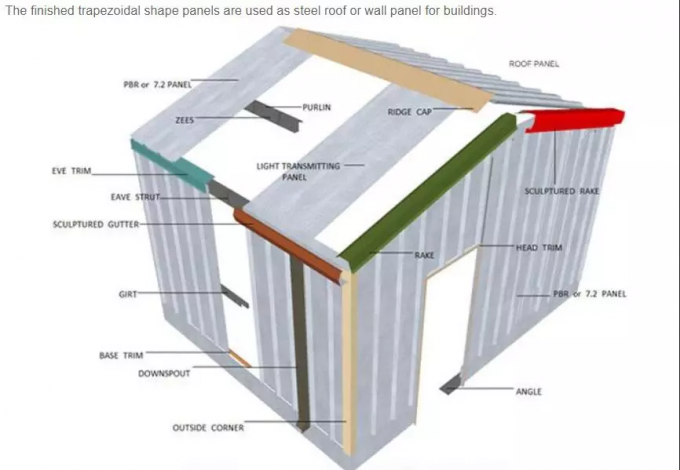

The following picture can help you understand much better for the application of the roof profiles .

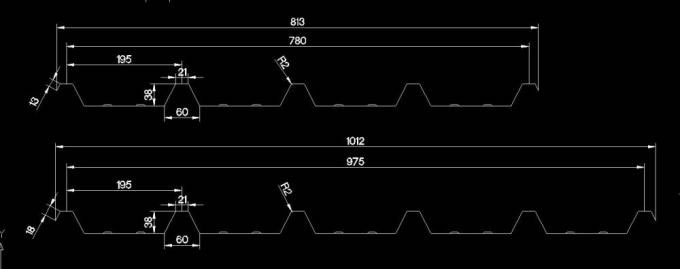

Profile And Finished Roof profile by the Metal Roofing Panel Machine

The following drawing is designed for the Algeria client , depend on his needs , one machine can make the two different profiles . This profiles is very popular in Algeria .

Also the other advantage of this Roof Panel Roll Forming Machine is its speed , we adopt the gear box transmission system . so that it can reach 35 meter per minute , very fast compared with the common machine . Because the common machine can only reach 8-12 meter per minute . If the client has a large demant of the profile , this design is a good choice for you .

Main Specification Of Roof And Wall Panel Roll Forming Machine

| No. | Type | Specification | |

| 1 | Row Material | Type | Aluminum / Steel / Galvanized Panel |

| Feeding width | 1200mm | ||

| Thickness | 1200mm | ||

| 2 | Main body | Roller station | 22 Steps |

| Diameter of shaft | ¢105mm | ||

| Shaft material | 45# Steel , Heat Treatment and Polishing | ||

| Roller material | 45# Steel , Heat Treatment and Polishing | ||

| Frame | 400mm H Steel | ||

| Frame thickenss | 22 mm | ||

| Operation | Manual and Automatic | ||

| Working speed | 30-35m/min | ||

| Size (L*W*H) | About 11500*1650*1450mm | ||

| Weight | About 3.5 Tons | ||

| Cutting type | Hydraulic cutting | ||

| Material of blade | Cr12, HRC60-62°C | ||

| 3 | Power | Motor power | 15 kw |

| Hydraulic power | 4 kw | ||

| Voltage | 380V 50Hz 3phases or Customerization | ||

| Driving way | Gear box | ||

Working Flow Of metal roof panel machine

5 Tons Decoiler — Panel Feeding And Guiding Table — Main Roll Forming Machine — PLC Control System — Hydraulic Cutting Device — Product Receiving Table

More picture of the metal roof roll forming machine

When we ship the roof panel machine to you , we will also send the client the necessary spare parts .

* 5T Decoiler………………………………1 Set

* Discharge Table………………………………2 Set

* The tool box ………………………………..1 set

Application

This type of sheet are widly used in warehouse, workshop, roofing and other part. It has a large market.

Loading And Shipping

* We will packed water proof paper on the machine .

* This Glazed Tile Roll Forming Machine need 1*40 GP container to load .

* Fix machine by steel wire rope, to ensure it will not damage when shaking on sea.

* We will take photos and videos for customer when loading to container .