Drywall Corner Bead 90/ 130 Degree Machine 90°/130° Corner Bead Roll Forming Machine

Drywall Corner Bead 90/ 130 Degree Machine 90°/130° Corner Bead Roll Forming Machine

Description of 90°/130° Corner Bead Roll Forming Machine

- The Zhongtuo Corner BeadMachine is constructed from high-quality, zinc-coated steel, providing strong protection for external corners.

- These trims are designed to improve compound adhesion and can be securely applied using nails or screws.

- Measuring 1-1/4″ x 1-1/4″, the ZTFRM metal corner bead machine is available in both 90-degree and 130-degree angles, making it ideal for “open” corners.

- This corner bead can be easily fastened with nails or screws, ensuring corners are well-protected and achieving a sharp, clean finish after compound application.

- Specifically engineered for 130º wide angle corners, this drywall corner bead is available with either 1 1/4″ or 1 1/8″ flanges to accommodate 135º corners.

Our machines are capable of producing corner beads with angles ranging from 130˚ to 135˚, ensuring excellent protection and precision. The incorporation of holes and a knurled surface enhances adhesion for the joint compound, resulting in a more secure application.

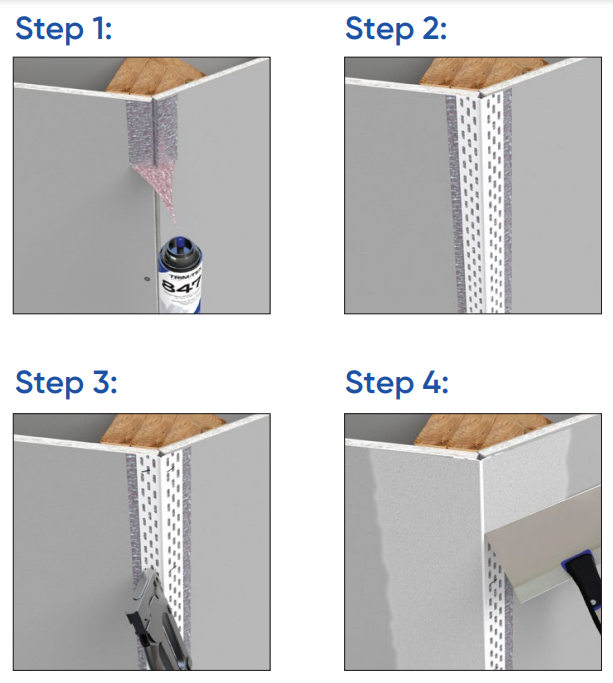

Profile Drawing And Application:

Before Installation:

Begin by measuring, cutting, and dry-fitting the bead, ensuring to leave a ½” gap from the floor.

Step 1:

Apply spray adhesive to both the bead and the edge of the drywall.

Step 2:

Position the bead and press it firmly in place, applying pressure to the mud legs.

Step 3:

Secure the bead by stapling every 6”-8” using ½” staples.

Step 4:

Complete the installation by applying drywall compound.

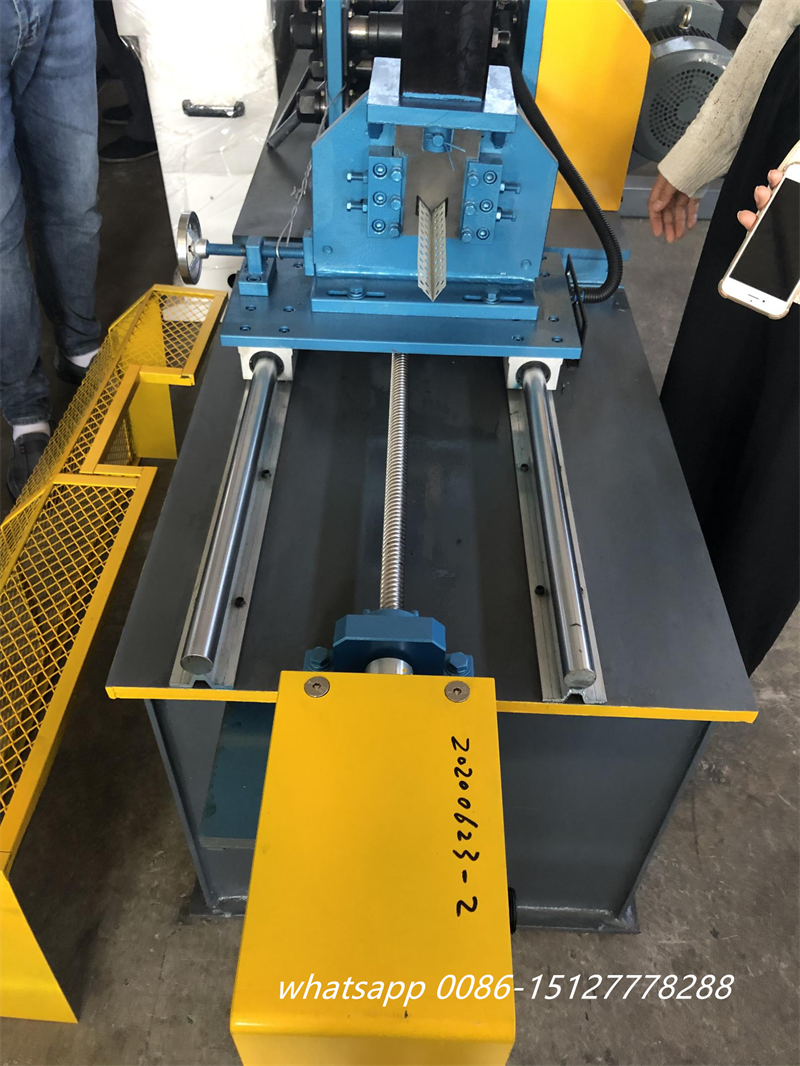

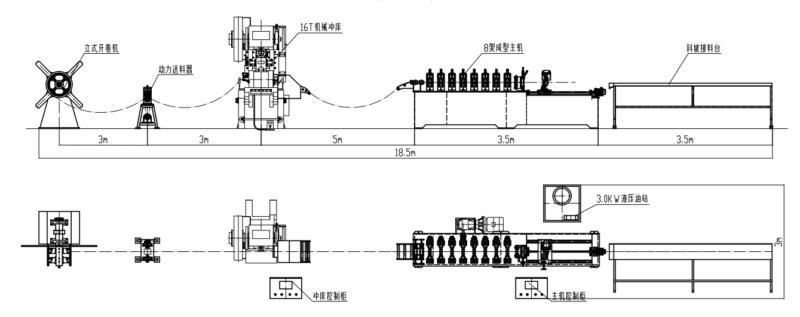

The 90°/130°Corner bead Roll Forming Machine working flow:

The Technical Specifications Of The 90°/130°Corner bead Roll Forming Machine:

| 90°/130° Corner bead rolling forming machine | ||

| 1.Formed Material | GI | Thickness: 0.4-0.6 mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 12rows(As your requirement) |

| Diameter of shaft | 45mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 3T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | 0-70m/min(without knurling) 0-60m/min(with knurling) | Speed is adjustable according to customer’s request |

More pictures of the machine: