H7 Slag Stop Machine and H5 1/2 Slag Stop ,H6F Slag Stop Roll Forming Machine

H7 Slag Stop Machine and H5 1/2 Slag Stop ,H6F Slag Stop Roll Forming Machine

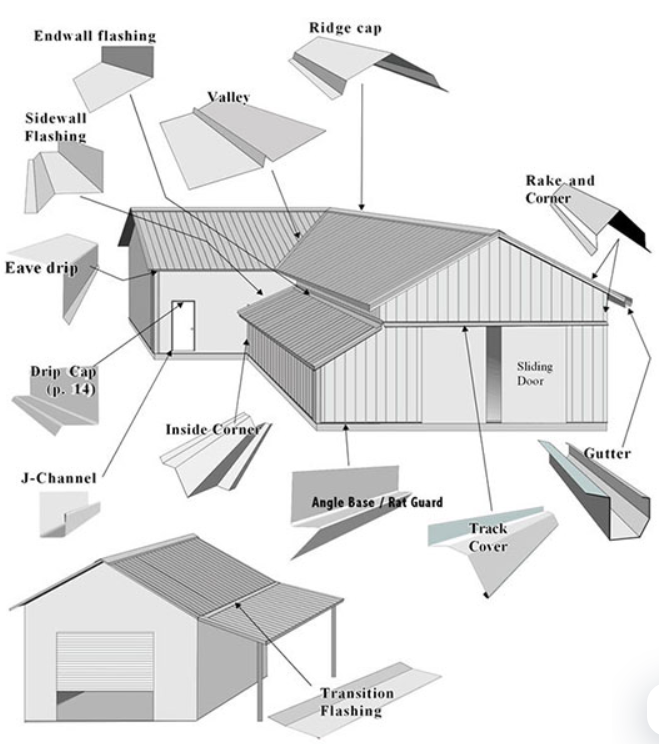

Description of Drip Edge Roll Forming Machine

- Protects and covers the roof’s edge effectively.

- Directs runoff straight into the gutters.

- Ideal for both new constructions and reroofing projects.

- Installed along the roof’s gutter line.

- Acts as a starter strip to ensure proper alignment of shingles.

- Features a kick-out at the bottom to redirect rainwater away from the fascia board, helping to prevent rot.

- Constructed from standard gauge material, with a 5/8 inch overhang included in the face dimensions.

Drip Edge Flashing Roll Forming Machine

The drip edge flashing roll forming machine is a specialized tool designed to produce drip edge flashing components. These components are essential for safeguarding building structures from water damage by effectively channeling rainwater away from roofs and walls.

Typical Applications:

- Roofing Industry: Manufacturing drip edges for both residential and commercial properties.

- Construction: Fabricating custom flashing components for various structural needs.

- Manufacturing: Creating profiles for ore-engineered building systems.

H7 /H8 Drip Edge Machine :

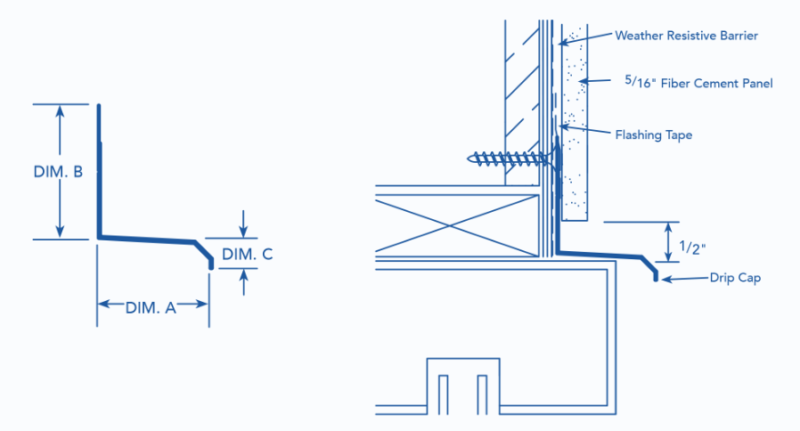

The Drip Cap provides a traditional reveal between the horizontal ends of 5/16” fiber cement panels. Its angled design effectively channels moisture away from the building’s envelope.

This profile is perfect for use as headers in window and door applications, as well as serving as a starter in a rain screen system. The Drip Cap comes in 12-foot lengths and is offered in a variety of finishes.

Note:

To be used in a horizontal application. Attach panel in accordance with the ZTRFM’s fastening schedule.

Profile Drawing:

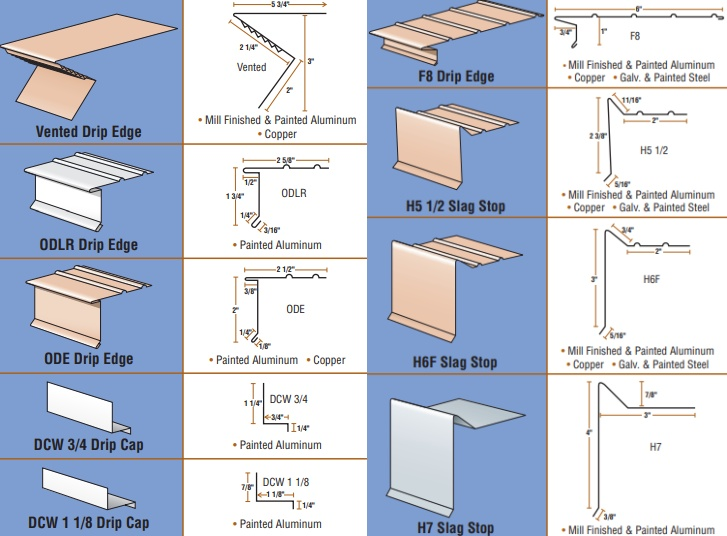

A metal trim is installed around the roof’s perimeter to achieve a polished and finished look. Utilizing a roof edge roll former, this trim can be shaped into complex designs and patterns, offering a customized aesthetic that enhances the building’s architecture. Roof edges can be crafted from various materials such as aluminum, steel, and copper, and are frequently coated to provide protection against corrosion and weathering.

ZHONGTUO Drip Edge Machine Services providing a solution for all roof edge requirements, including concreting on metal Drip Edge and roof Drip Edge machine.

ZHONGTUO Machinery provides metal Drip Edge machines, ZHONGTUO Machinery is also capable of manufacturing other types of metal Drip Edge roll forming machines.In addition, we specialize in:

- C3 Drip Edge

- F8 Drip Edge

- H5 1/2 Slag Stop

- H6F Slag Stop

- H7 Slag Stop

- ODLR Drip Edge

- Vented Drip Edge

- DCW 3/4 Drip Cap

- DCW 1 1/8 Drip Cap

If you have any interest in these machines, please don’t hesitate to contact ZHONGTUO Machinery for more information.

Roof drip edges are available in nearly fifty different profiles, sizes, and shapes to accommodate various roof types, slopes, and other specific roofing needs.

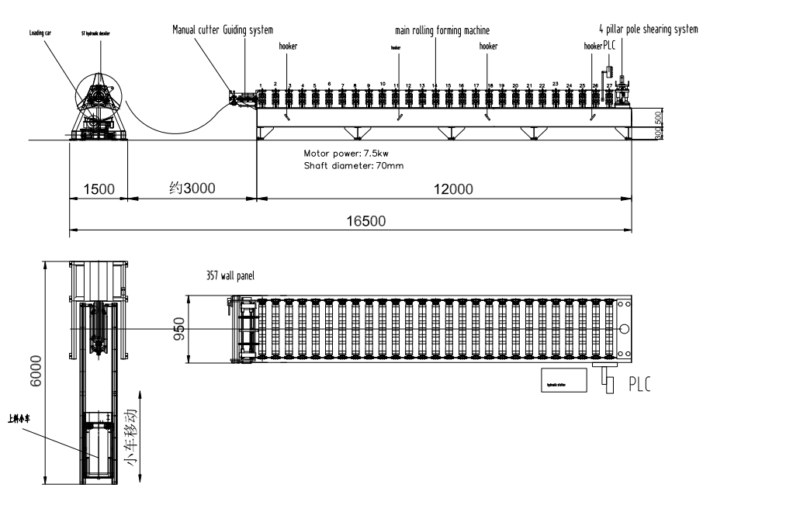

Drip Edge Roll Forming Machine working flow:

Despoiler-Feeding Material-Roll Forming-Servo Cutting-Automatic s tacker

The Technical Specifications Of The Drip Edge Roll Forming Machine Rolling Forming Machine:

|

Drip Edge rolling forming machine |

|||

| Series | Details | Parameter | Comment |

| Material | Raw material | Steel | Customer confirmed |

| Material thickness | 0.4-0.6 mm | ||

| Decoiler | Structure | Manual passive type | The standard one to match the production line |

| Single head type | |||

| Loading capacity | 2.5 Tons | ||

| Coil inner diameter | 450-550 mm | ||

|

Roll forming machine |

Guiding device | Placed on the machine by seller | |

| Rolling shaft material | 45# STEEL | ||

| Shaft diameter | 50 mm | ||

| Roller material | GB-Cr12 | ||

| Rolling station | 12 stations | ||

| Work speed | 45 m/min | ||

| Machine structure | Vertical memorial arch frame | ||

| Machine basic frame | Steel plate welded | ||

| Bearing | Roller bearing | Famous brand of Harbin | |

| Work power | 7.5 kw | ||

| Transmission | By gear | With cover | |

| Safety cover | available | ||

|

Appearance |

Good appearance with no burrs in steel body nor traces of rust or defects in painting.

Good electrical and hydraulic cable organization Car painting make the machine more glossy |

We confirm each detail can match the standard, ensure the machine is 100% new! | |

| Decoiler, we can change to hydraulic one if you need. | |||

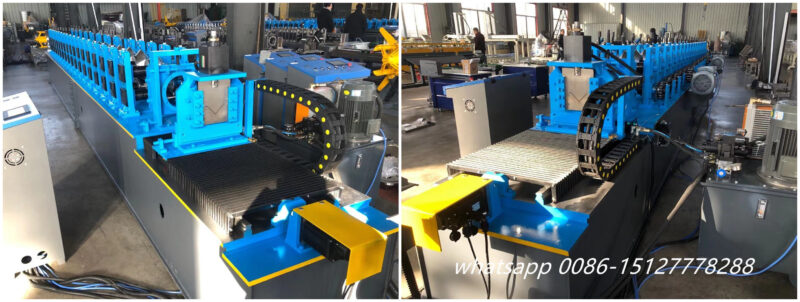

More pictures of the machine: