TR50 Roof Decking Rolling Forming Machine Steel Structure Floor Deck Roll Forming Machine

TR50 Roof Decking Rolling Forming Machine Steel Structure Floor Deck Roll Forming Machine

Description of TR50 deck panels roll forming machine

Cangzhou Zhongtuo Cold Roll Forming Machine Company is a leading manufacturer of various deck machines, such as roof deck machines, floor deck machines, and TR50 deck machines.

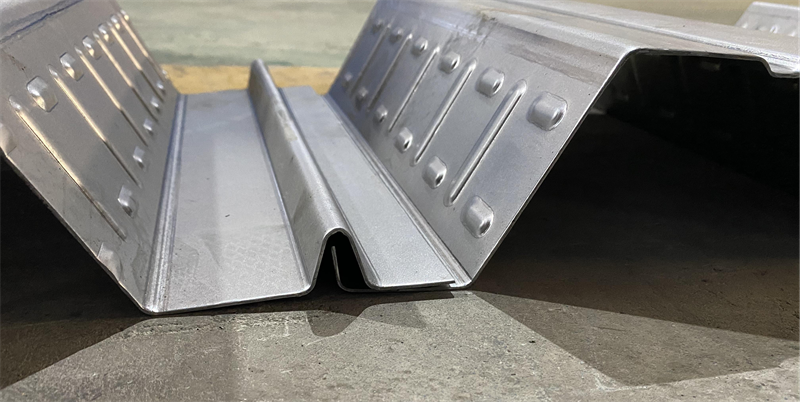

This series of floor deck roll forming machines is designed to produce high-quality metal decks, also known as floor-bearing steel plates. These steel plates are primarily used for floor slabs and are characterized by their high peak and strength. The production process is highly automated, resulting in reduced costs.

The steel floor support plates created by our roll forming machines feature a simple shape with substantial waviness and high strength. After installation, a spot-welded reinforcement mesh is added and integrated with on-site poured concrete, ensuring excellent adhesion. In high-rise buildings, this system can eliminate the need for steel formwork and reduce floor load.

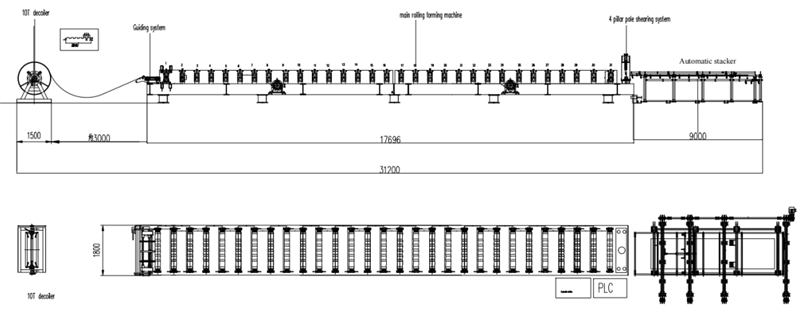

Our floor-bearing steel plate roll forming machine consists of several components: Decoiler, a feed introduction platform, a forming motor, a punching device, a forming cutting device, a hydraulic station, and a computer control cabinet.

Introduced in 2018, the TR50 profile serves as a non-composite permanent shuttering deck, offering a cost-effective solution for high-quality results. This profile is intended solely for use as formwork, with the reinforcement within the slab designed by a structural engineer..Our TR50 deck machines are engineered with enhanced durability, utilizing a solid 90mm diameter shaft compared to the typical 85mm shaft found in standard deck machines. Additionally, they are equipped with more powerful motors—providing greater efficiency and performance.

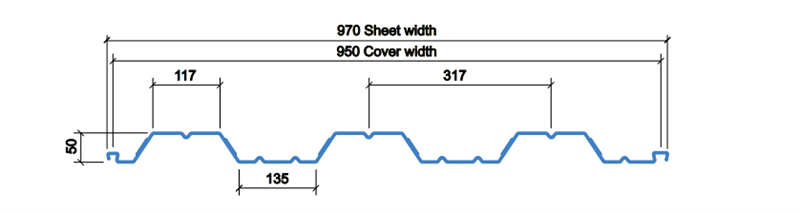

Profile drawing:

TR50 Roof Decking Description

- Deck Type: TR50 deck

- Supports un-propped spans of up to 3.0 meters.

- Serves as formwork for non-composite RCC floor and roof slabs.

- Features a flexible side-lap detail for precise control of cover width.

- Trough stiffener positioning is optimized to align with stud placement, reducing the need for additional checks on-site.

- The cover width is optimized to facilitate faster installation.

Work Chart for the Decking Machine:

The technical specifications of the TR50 Roof Decking Rolling Forming Machine:

|

ISO CE Certificate TR 50 deck panels Roof deck roll forming machine |

||

| 1.Formed Material | Formed Material | Thickness:0.7-1.2mm Width:1220mm (as request) |

| 2.Decoiler | Hydraulic automatic decoiler | Capacity:10T

With loading car |

| 3.Main body | Roller station | 34 rows(As your requirement) |

| Diameter of shaft | 95mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | 400 H steel | |

| Drive | Double chain transmission | |

| Dimension(L*W*H) | About 18500*1700*1600(customize) | |

| Weight | About 15T | |

| 4.Cutter | Hydraulic | Cutting blade material:Cr12 with quenched treatment |

| 5.Power | Motor Power | 18.5kw*2 sets |

| Hydraulic system power | 5.5KW | |

| 6.Voltage | 220V 50Hz 3Phase | As requirement |

| 7.Control system | PLC and touch screen | Delta brand |

| Low pressure apparatus | Schneider | |

| Language | Chinese and English | |

| 8.Forming Speed | 8-15m/min | The speed is adjustable |

More pictures of the machine: