TR60 Roof Decking Rolling Forming Machine TR60 And TR80 Profile Deck Machines

TR60 Roof Decking Rolling Forming Machine TR60 And TR80 Profile Deck Machines

Description of TR60 And TR80 profile deck machines

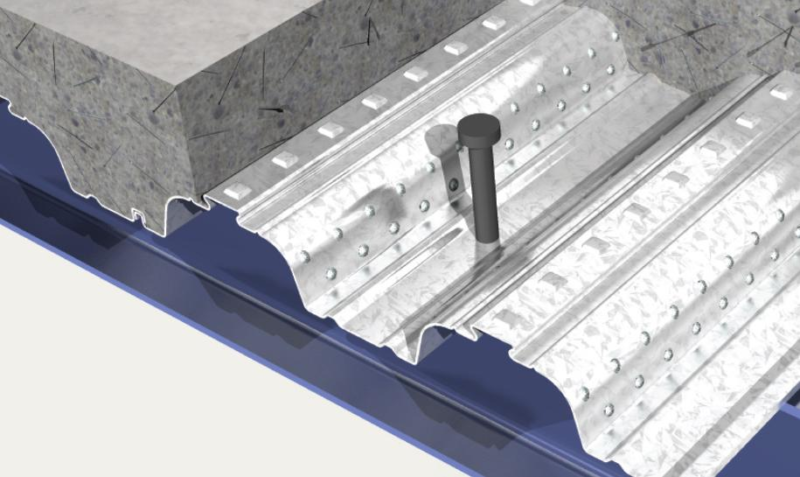

Floor decking is essential in construction, providing a structural surface for floors that can bear heavy loads and endure various environmental conditions. There are different types of floor decking materials and systems, each with distinct features and uses. Below are some common types of floor decking roll forming machines:

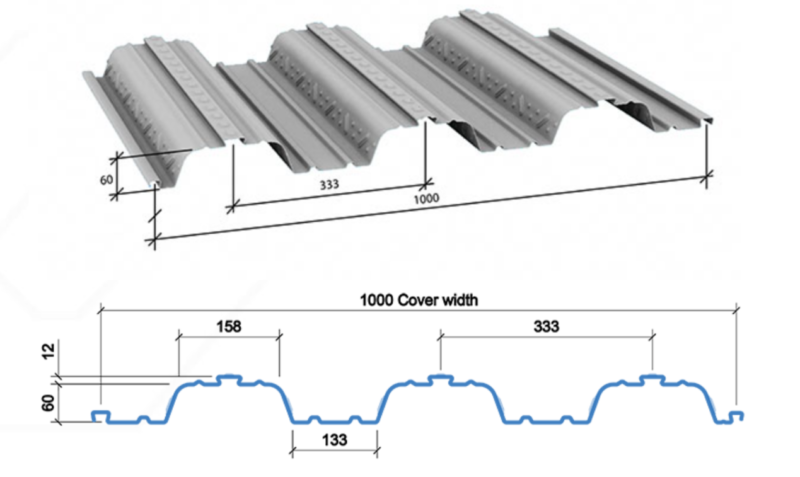

TR60 Profile drawing:

TR60 Roof Decking Description

- Deck Type: TR60 deck

- Effective Width: 600mm

- Effective Width Tolerance: ±5mm

- Material Thickness:0.8-1.2mm

- The Length Of Tolerance:±1(4m)

- Applicable Material:Galvanized Sheet(GI)

- Inspection Thickness:0.9mm

- With yield strength:G550Mpa

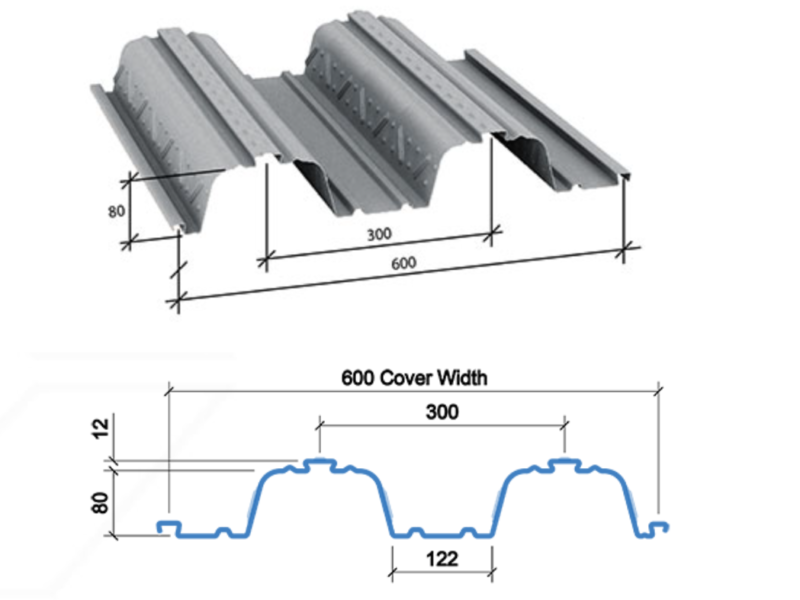

TR80 Profile drawing:

ZHONGTUO Machinery is also capable of manufacturing other types of metal deck roll forming machines, such as the floor deck TR60+, Comflor 80, Losacero 25, and and , among others.

If you have any interest in these machines, please don’t hesitate to contact ZHONGTUO Machinery for more information.

The TR80+ floor deck profile is a widely used British profile design with nominal thicknesses of 0.9mm, 1mm, and 1.2mm. It typically uses S350 or S450 grade steel material, with a profile depth of 80/92mm. This 80mm deep trapezoidal profile is highly favored for low to medium-rise buildings because it provides long unpropped spans, reducing the need for numerous structural support members. Additionally, one of our customer requirements includes a 4mm embossment height, which is a challenging profile to achieve with a roll forming machine. To meet this demand, we utilize 34 forming stations, ensuring the final product has precise dimensions and a smooth, flat surface.

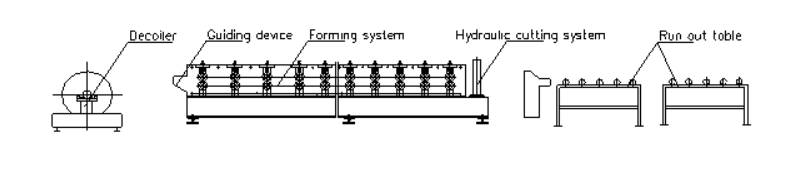

Work Flow of the Decking Machine:

Decoiler→Feeding Device→Embossing→Roll Forming System→Hydraulic Cutting System→Exit Rack

| Floor Deck TR80+ Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Coil | Thickness(MM):0.8-1.5mm |

| B) S450 | ||

| C) S450 | ||

| Yield strength : | 350 – 450 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN): | 0-20 | according to your requirement (Optional) |

| Forming station : | 34 stands | |

| Decoiler : | Manual decoiler | Hydraulic decoiler (Optional) |

| Punching system | No | Hydraulic punching or Punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | Siemens |

| Driving system : | Chain drive | Gearbox drive (Optional) |

| Machine structure: | Wall panel station | Forged Iron station or torri stand structure (Optional) |

| Rollers’ material : | GCr15 | |

| Cutting system : | Post-cutting | Pre-cutting (optional) |

| Power supply : | 380V 50Hz | according to your requirement |

| Machine color : | Industrial blue | according to your requirement |

More pictures of the machine: