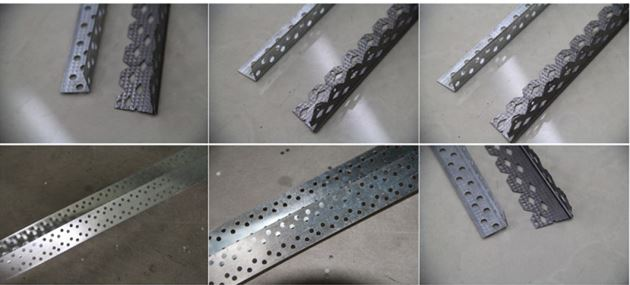

Zhongtuo wall angle roll former with punching holes

Here are some pictures for your reference:

Features of Zhongtuo wall angle roll former with punching holes:

- Our machine could make roll forming and punching as a whole, and then the working speed could be enhanced greatly.

- Punching hole types could be customized according to your needs.

- For the punching dies could be changed fast and easily.

- Low energy consuming and high working speed.

- Beautiful shape of machine, it takes small space in the factory, motor will be covered in the steel frame as a whole.

- Thick and hard steel frame of the machine for long time use.

- Painting part, we will choose the China homemade best painting for long time anti corrosion.

Work flow of wall angle roll former with punching holes:

Basic parameters of this machine:

| Description | Introduction | Customer needs | |

| Working efficiency | 5-15m/min | ||

| Thickness of Material | 0.2-0.55mm | According to your needs. | |

| Width of material | 35mm—65mm | According to your needs. | |

| Control system | PLC | Delta | |

| Uncoiler system | 1.5 Ton | 500mm | |

| Forming by rolling | Roll 9 rows | ||

| Roller material | Gcr12MoV quenched | ||

| Shaft and the diameter of axle | 45#Aluminium processing

diameter of 40mm |

||

| Main part power | 3kw | ||

| Hydraulic motor power | 3kw | ||

| Hydraulic pressure | 20Mpa | ||

| Scissor material | Gcr12MoV quenched | ||

| length tolerance | 3m±1.0mm | ||

| voltage | 380V, 50HZ,3 phase | Adjustable by customer | |

| Frame form | Gantry arch type | ||

| Driving Method | Gear box | ||

| Color | Yellow and blue | adjustable | |

| Working Size | length*Width*Height | ||

| Coiler feeder | 1.5kw | ||

| Punching machine | Gcr12MoV quenched | ||

| Punching moulds | Each type one set | ||